1. The sliding block adopts the torsional shaft synchronization mechanism, and the two ends of the torsional shaft are installed with high precision taper centering bearing (K type), and the left end is equipped with eccentric adjusting mechanism, making the sliding block synchronous adjustment convenient and reliable.

2. The use of upper die deflection compensation mechanism, through adjustment can make the upper die mouth on the full length of the machine to obtain a specific curve, to compensate for the mechanical loading table and slide produced by the deflection, improve the workpiece bending accuracy.

3. In the Angle adjustment, the worm gear reducer drives the formation of the movement of the mechanical block in the cylinder, and the value of the cylinder position is displayed by the travel counter.

4. The upper and lower adjusting mechanism is arranged at the fixed place of the workbench and the wall panel, which makes the adjustment convenient and reliable when the bending Angle is slightly different.

5. The column right side is equipped with remote pressure regulating valve, so that the size of the system pressure adjustment, convenient and reliable.

| No. | name | parameter | Unit | |

| 1 | Nominal Pressure | 1000 | KN | |

| 2 | Length of Table | 4000 | mm | |

| 3 | Distance between Housings | 3160 | mm | |

| 4 | Throat Depth | 330 | mm | |

| 5 | Ram stroke | 120 | mm | |

| 6 | Open MAX Height | 380 | mm | |

| 7 | Overall Dimensions |

L | 4100mm | mm |

| W | 1600mm | mm | ||

| H | 2600mm | mm | ||

| 8 | Main motor power | 7.5 | Kw | |

| 9 | Machine weight | 8 | Tons | |

| 10 | Voltage | 220/380/420/660 | V | |

| Model | Weight (t) | Cylinder Diameter (mm) | Stroke (mm) | Wallboard (mm) | Slider (mm) | Bench Riser (mm) |

| WC67K-30T1600 | 1.4 | 95 | 80 | 18 | 20 | 20 |

| WC67K-40T2200 | 2.1 | 110 | 100 | 25 | 30 | 25 |

| WC67K-40T2500 | 2.3 | 110 | 100 | 25 | 30 | 25 |

| WC67K-63T2500 | 3.6 | 140 | 120 | 30 | 35 | 35 |

| WC67K-63T3200 | 4 | 140 | 120 | 30 | 35 | 40 |

| WC67K-80T2500 | 4 | 160 | 120 | 35 | 40 | 40 |

| WC67K-80T3200 | 5 | 160 | 120 | 35 | 40 | 40 |

| WC67K-80T4000 | 6 | 160 | 120 | 35 | 40 | 45 |

| WC67K-100T2500 | 5 | 180 | 140 | 40 | 50 | 50 |

| WC67K-100T3200 | 6 | 180 | 140 | 40 | 50 | 50 |

| WC67K-100T4000 | 7.8 | 180 | 140 | 40 | 50 | 60 |

| WC67K-125T3200 | 7 | 190 | 140 | 45 | 50 | 50 |

| WC67K-125T4000 | 8 | 190 | 140 | 45 | 50 | 60 |

| WC67K-160T3200 | 8 | 210 | 190 | 50 | 60 | 60 |

| WC67K-160T4000 | 9 | 210 | 190 | 50 | 60 | 60 |

| WC67K-200T3200 | 11 | 240 | 190 | 60 | 70 | 70 |

| WC67K-200T4000 | 13 | 240 | 190 | 60 | 70 | 70 |

| WC67K-200T5000 | 15 | 240 | 190 | 60 | 70 | 70 |

| WC67K-200T6000 | 17 | 240 | 190 | 70 | 80 | 80 |

| WC67K-250T4000 | 14 | 280 | 250 | 70 | 70 | 70 |

| WC67K-250T5000 | 16 | 280 | 250 | 70 | 70 | 70 |

| WC67K-250T6000 | 19 | 280 | 250 | 70 | 70 | 80 |

| WC67K-300T4000 | 15 | 300 | 250 | 70 | 80 | 90 |

| WC67K-300T5000 | 17.5 | 300 | 250 | 70 | 80 | 90 |

| WC67K-300T6000 | 25 | 300 | 250 | 80 | 90 | 90 |

| WC67K-400T4000 | 21 | 350 | 250 | 80 | 90 | 90 |

| WC67K-400T6000 | 31 | 350 | 250 | 90 | 100 | 100 |

| WC67K-500T4000 | 26 | 380 | 300 | |||

| WC67K-500T6000 | 40 | 380 | 300 |

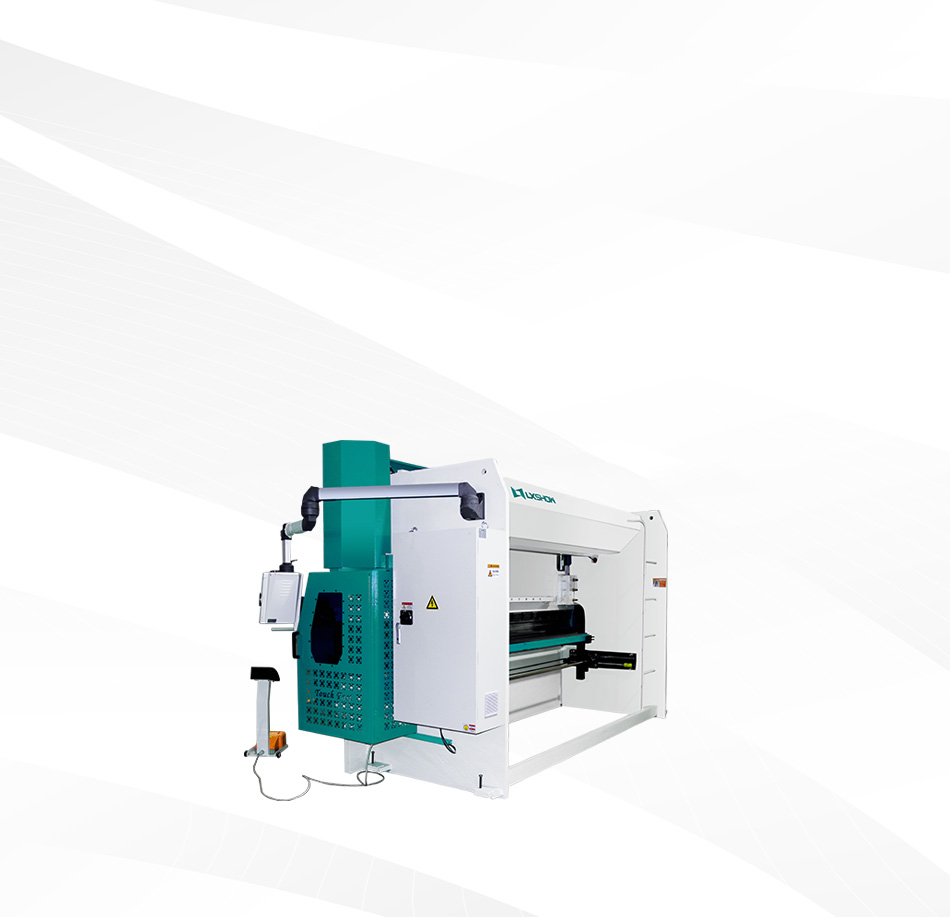

Product Details

Control System:Estun E21

1 Easy to operate: This system has multi-step programming, can be changed at any time different sizes.

2 Manual function: Convenient debugging and installation, with manual mode to adjust the required size.

Front Bracket

Placed on the side of the table, fixed by screws. It can be used as support when bending wide and long plates.

Back Barrier

The rear stopper mechanism with T-type lead screw matching rod is driven by motor. Positioning stop refers to the aluminum alloy beam can easily move around and bend the workpiece at will.

Electrical Machinery

Electrical Machinery

Foot switch

Control the start and stop of the bending machine to achieve precise control of the bending process

Sample Show & Industry

Packaging

Factory

Our Service

Customer Visit

Off-line Activity

FAQ

Q: Do you have CE document and other documents for customs clearance?

A: Yes, we have CE, Provide you with a one-stop service.

At first we will show you and and after shipment we will give you CE/Packing list/Commercial Invoice/ Sales contract for customs clearance.

A:Could you tell me your materials:cs or ss and their thickness? And the biggest bending width? Then i will confirm the machine model for you.